Main feature

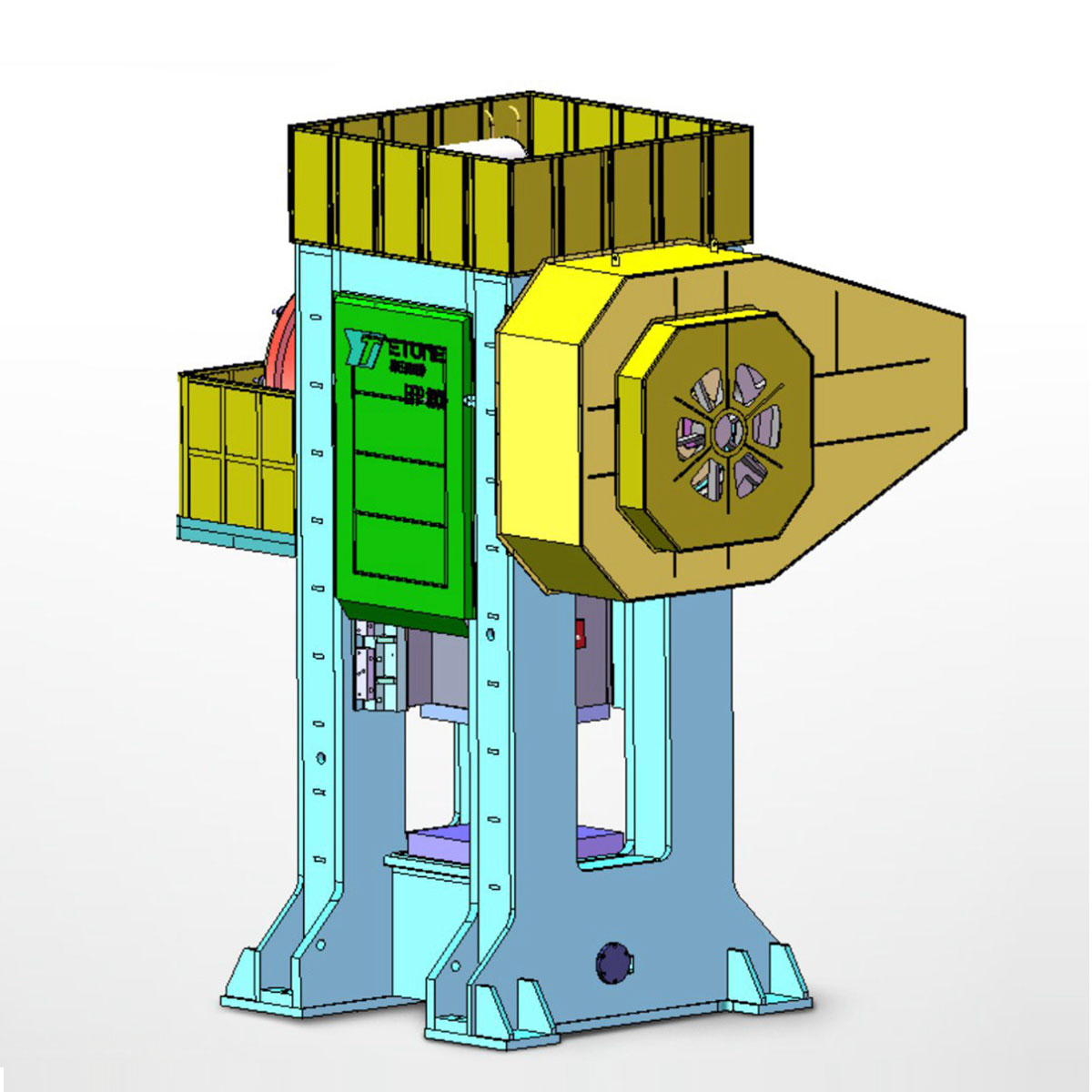

• Lateral feeding with reasonable side window space, wide-body double support connecting rod and lengthened guide rail design, strong antibiased load ability, multi-station automatic forging combined with stepping manipulator.

• Floating insert type clutch friction block design, friction block than small pressure longer life, than the traditional structure replacement. The period is 2 to 3 times longer. Large braking torque, small braking Angle, simple and reliable structure and easy maintenance. Brake with a forced water cooling system, low temperature rise can achieve highspeed single operation.

• The eight-sided guide rail design has high guidance accuracy and the forging quality has been improved.

• With anti-stuck mold structure design to provide customers with high added value products.

• Applicable forgings: disc, gear, gear blank, belt wheel, wheel shell, etc.;

Long shaft, gear with handle, wheel shaft, fork shaft, etc.; Special-shaped parts, such as steering, crankshaft, CAM, connecting rod, chain link, etc.

Technical parameters

Name |

Gauge |

EFP-400 |

EFP-650 |

EFP-800 |

EFP-1000 |

EFP-1300 |

tonnage |

on |

400 |

650 |

800 |

1000 |

1300 |

Unloaded continuous stroke number |

PM |

90~110 |

90~100 |

85~100 |

80~90 |

75~95 |

Slide stroke length |

mm |

160 |

200 |

220 |

250 |

260 |

Die height |

mm |

500 |

555 |

600 |

755 |

845 |

Slide adjustment |

mm |

8 |

10 |

10 |

10 |

12 |

Slide area (LRxFB) |

|

550x600 |

650 × 700 |

750 × 800 |

920 × 920 |

920 × 103 |

Bolster area (LRxFB) |

Xm |

550x600 |

700 × 800 |

800 × 900 |

1100 × 1050 |

950 × 1300 |

BoLster area thickness |

mm |

110 |

120 |

130 |

150 |

150 |

Upper ejector device |

Type |

|

Hydraulic/National Gas Law Capital |

Hydraulic/National Gas Law Tour |

Hydraulic/hydrogen law tour |

Hydraulic/gas law tour |

Hydraulic/National Gas Law Capital |

Ejector force/stroke |

on/mr |

4/50 |

6/30 |

6/50 |

10/30 |

10/30 |

Upper ejector device |

Type |

|

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Ejector force/stroke |

ton/me |

6/16 |

0/16(50) |

2/18(50) |

20/20(50) |

20/30(50) |

Main motor power |

Kw |

30 |

37 |

45 |

55 |

90 |

Name |

Gauge |

EFP-1600 |

EFP-2000 |

EFP-2500 |

EFP-3150 |

EFP-4000 |

tonnage |

on |

1600 |

2000 |

2500 |

3150 |

4000 |

Unloaded continuous stroke number |

PM |

75~85 |

65~85 |

70~80 |

50~60 |

40~50 |

Slide stroke length |

mm |

300 |

300 |

320 |

340 |

360 |

Die height |

mm |

915 |

915 |

900 |

000 |

100 |

Slide adjustment |

mm |

15 |

20 |

22.5 |

25 |

28 |

Slide area (LRxFB) |

|

100 × 1000 |

180x1260 |

260 × 138 |

1300 × 130 |

460 × 1710 |

Bolster area (LRxFB) |

Xm |

1200 × 1200 |

1210 × 1530 |

1300 × 1700 |

1350 × 1300 |

1500 × 2050 |

BoLster area thickness |

mm |

180 |

200 |

220 |

240 |

250 |

Upper ejector device |

Type |

|

Hydraulic/Hydrogen Bomb Tour |

Hydraulic/hydrogen legal capital |

Hydraulic/Hydrogen Bomb |

Hydraulic/Hydrogen Bomb Tour |

Hydraulic/high gas bomb |

Ejector force/stroke |

on/mr |

10/30 |

10/40 |

10/30 |

16/48 |

20/52 |

Upper ejector device |

Type |

|

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Hydraulic/Mechanical |

Ejector force/stroke |

ton/me |

24/37(50) |

30/40(50) |

40/44(80) |

48/50 |

60/52(200) |

Main motor power |

Kw |

110 |

160 |

185 |

220 |

315 |

The above technical parameters can be modifhed as required.

Upper and lower topping form and parameters can be designed according to customer

Mobile: +86-15990568092

Mobile: +86-15990568092 Email: china_etone@163.com

Email: china_etone@163.com WhatsApp: +84 333 853 031

WhatsApp: +84 333 853 031 Wechat: 15990568092

Wechat: 15990568092 Contact: Mr.Bao

Contact: Mr.Bao Addess: Yinzhou Distrist, Ningbo, China

Addess: Yinzhou Distrist, Ningbo, China