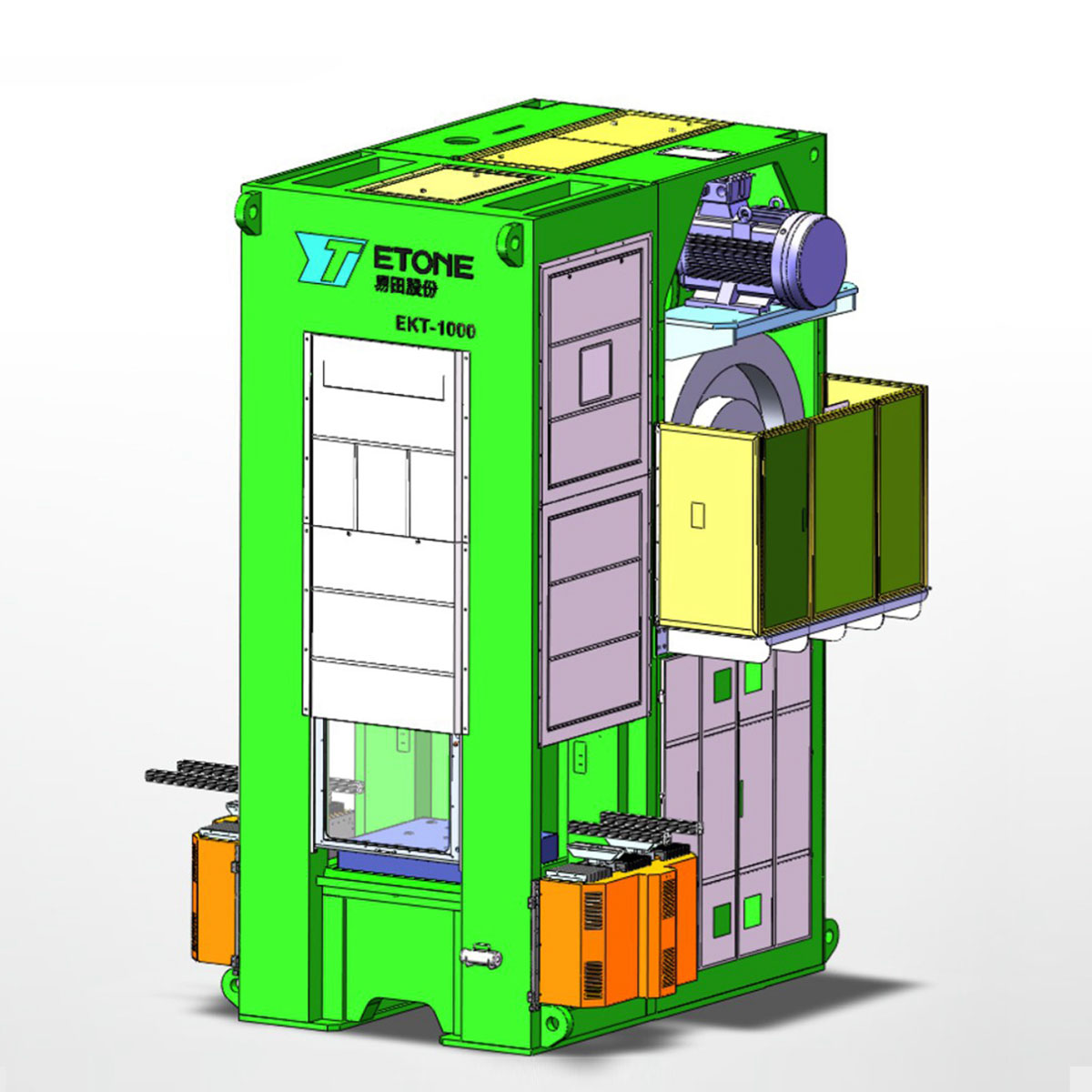

EKT Series Knuckle Cold &Warm Forging Press

Cold-temperature forging press is a professional equipment for processing cold-temperature forging process precision forging, which belongs to the feld of precision die forging, widely used in automobiles, ships, aviation, hardware tools, engineering machinery and other fhelds.

Main feature • The structure of the fuselage is reasonable, the rigidity is high, the comprehensive clearance is small, and the product accuracy and the service life of the mold are improved. • The speed of the slider near the bottom dead center is very slow, creating maximum pressure near the end of the working stroke and maintaining it for a long time. The processing range is wide, the position accuracy of the bottom dead point is high, and the working energy is high. • The slider adjusting motor uses a servo motor with a high-precision encoder to adjust the height of the slider, allowing the closing height, to be accurate to 0.01mm. • Using wet clutch brake ,noise and vibration is small. • Applicable forgings: gear, bell shell, transmission intermediate shaft/output shaft, claw pole, etc. Technical parameters

The above technical parameters can be modifhed as required. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Contact Us

Mobile: +86-15990568092

Mobile: +86-15990568092

Email: china_etone@163.com

Email: china_etone@163.com

WhatsApp: +84 333 853 031

WhatsApp: +84 333 853 031

Wechat: 15990568092

Wechat: 15990568092

Contact: Mr.Bao

Contact: Mr.Bao

Addess: Yinzhou Distrist, Ningbo, China

Addess: Yinzhou Distrist, Ningbo, China